Marble Saw Blades: A Complete Guide

Marble is a beautiful and versatile natural stone widely used in construction, interior design, and decorative applications. It’s commonly used for countertops, flooring, sculptures, and other ornamental features. However, cutting marble can be tricky due to its hardness, brittleness, and the risk of chipping or cracking if not handled properly. The solution to these challenges lies in using specialized marble saw blades that are designed to deliver precise, clean cuts while minimizing damage to the stone.

This article explores everything you need to know about marble saw blades, from what they are, how they work, to how to choose the right one for your specific needs.

What Are Marble Saw Blades?

Marble saw blades are cutting tools designed specifically for slicing through marble and other similar soft stones like limestone and travertine. They are designed to provide a clean, precise cut while minimizing the risk of chipping or damaging the marble surface.

These saw blades are typically made with diamond segments embedded in the cutting edge. Diamond is one of the hardest materials available, making it an ideal choice for cutting hard, brittle materials like marble. Depending on the design of the blade, marble saw blades can be either segmented, continuous rim, or turbo.

Types of Marble Saw Blades

There are different types of saw blades that can be used for cutting marble, each designed for specific tasks and cutting conditions. The main types of marble saw blades are:

1. Continuous Rim Diamond Blades

Design: These blades feature a smooth, continuous cutting edge with no notches or interruptions.

Best For: Clean and precise cuts on marble, especially for delicate or detailed work like cutting countertops or tiles.

Advantages: They provide a smooth, chip-free cut and are ideal for cutting thinner marble slabs. The lack of notches ensures a cleaner finish, making them perfect for surface cuts that require precision.

Applications: Used for cutting marble slabs, tiles, and countertops.

2. Segmented Diamond Blades

Design: These blades have notched segments (usually with diamond edges) spaced around the rim. The segments allow for better heat dissipation and quicker material removal.

Best For: Rough cuts and general-purpose cutting, especially in thicker pieces of marble.

Advantages: They are more aggressive than continuous rim blades and can cut through tougher, thicker materials more quickly. Segmented blades also perform well in wet conditions.

Applications: Ideal for rough cuts in construction or demolition work, and for cutting through large marble slabs or blocks.

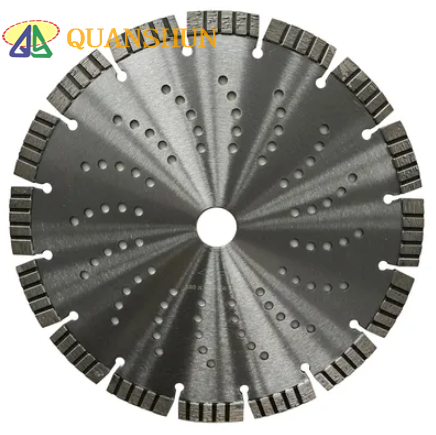

3. Turbo Diamond Blades

Design: Turbo blades combine the features of continuous and segmented blades. The cutting edge is continuous but has a spiral "turbo" design that helps with faster cutting and better cooling.

Best For: Faster, aggressive cuts while still maintaining smoothness.

Advantages: Turbo blades provide a good balance between speed and finish. They’re faster than continuous rim blades but still manage to produce smoother cuts than segmented blades.

Applications: Used for both rough and fine cuts, particularly in situations where speed and efficiency are important.

4. Wet Cutting Blades

Design: Wet cutting blades are designed to be used with a water cooling system to reduce friction, minimize dust, and cool the blade during use.

Best For: Cutting marble with minimal dust and avoiding overheating of the blade.

Advantages: Water lubrication reduces dust creation, lowers the risk of overheating, and helps achieve cleaner cuts with fewer chips.

Applications: Perfect for precision cuts, especially in environments where air quality is a concern or when cutting tiles and thinner slabs.

5. Dry Cutting Blades

Design: These blades are made for use without water. They tend to have larger gaps between segments and can withstand the high temperatures generated during dry cutting.

Best For: Cutting marble without access to water or in outdoor settings where water usage is not practical.

Advantages: No water required, making them ideal for portable saws or job sites where water isn’t readily available. They are also effective at cutting marble outdoors.

Applications: Often used in small or portable saws or for rough cuts on larger slabs.

How to Choose the Right Marble Saw Blade

Choosing the right marble saw blade depends on several factors, including the type of marble, the size and thickness of the material, and the specific cutting needs. Here’s how to select the best blade for your project:

1. Consider the Type of Marble

Soft Marble (e.g., Carrara marble): If you’re working with softer marble, a continuous rim blade will give you the cleanest cut.

Harder Marble (e.g., dark or veined marble): Harder marble requires more aggressive blades, such as segmented or turbo blades, to help speed up the cutting process.

2. Cutting Precision vs. Speed

If precision and smoothness are your priorities (such as when cutting countertops), opt for continuous rim blades.

If you need to cut quickly and efficiently, or if the cut won’t be visible, consider using segmented or turbo blades.

3. Wet vs. Dry Cutting

If possible, always choose wet cutting blades to reduce dust and improve cut quality. Wet cutting also extends the life of the blade.

For outdoor or portable jobs, where water isn’t available, a dry cutting blade might be necessary, though expect more dust and faster blade wear.

4. Blade Size and Thickness

Smaller blades (e.g., 4-7 inches) are ideal for precision cutting and tile work.

Larger blades (e.g., 12-16 inches) are suitable for cutting thicker marble slabs or larger materials. Larger blades provide more stability and help prevent warping during the cut.

5. Quality and Durability

Choose a high-quality diamond blade with a higher diamond concentration for better performance and longevity. High-quality blades are essential when cutting marble, as they provide better durability, cleaner cuts, and longer service life.

Tips for Cutting Marble

Always Use Water: For a cleaner cut and longer-lasting blade, always use water when possible. This will prevent dust and reduce the heat generated by cutting.

Use Proper Safety Gear: Always wear safety glasses, a dust mask, gloves, and ear protection when cutting marble. The cutting process generates a lot of dust and can be noisy.

Cut Slowly and Steadily: Don’t rush the cutting process. Allow the saw to do the work to reduce the risk of chipping or cracking the marble.

Support the Marble: Make sure the marble slab is well-supported to prevent it from shifting or breaking during the cut. Use a stable work surface or sawhorse.

Cool the Blade: If using a dry cutting blade, take regular breaks to allow the blade to cool down and avoid overheating.

Conclusion

Marble saw blades are essential tools for anyone working with marble, whether you're cutting slabs for countertops, tiles for flooring, or creating intricate carvings. By choosing the right type of blade for your specific needs, you can ensure clean, precise cuts, and prevent costly mistakes.

From continuous rim blades for fine cuts to segmented and turbo blades for rougher jobs, the key is to match the blade to the task at hand. When possible, consider using wet cutting blades for the best results, and always follow safety guidelines to protect yourself and your materials. With the right saw blade and techniques, you can make marble cutting both easier and more effective.

Diamond Wire & Band Saw Bl

Diamond Wire & Band Saw Bl

Marble Saw Blades: A Complete

Marble Saw Blades: A Complete

How to Choose the Right Saw Bl

How to Choose the Right Saw Bl

Why Special Saw Blades are Nee

Why Special Saw Blades are Nee