Why Special Saw Blades are Needed for Artificial Stone

Artificial stone is a dense and hard material, making it difficult to cut using standard saw blades. The composite nature of artificial stone, with its combination of natural minerals and resin, requires blades that are able to effectively manage both hardness and toughness.

Key characteristics of artificial stone that affect the cutting process include:

Hardness: Artificial stones often have a hardness level similar to or even higher than natural granite, making them resistant to cutting by regular saw blades.

Brittleness: Due to the resins used in artificial stones, they can be more brittle and prone to cracking if not handled properly.

Dust Generation: Cutting artificial stone generates a large amount of fine dust, which can be harmful to both the operator and the equipment. Proper blade design and dust collection are critical.

Types of Artificial Stone Saw Blades

There are several types of saw blades designed for cutting artificial stone. Each is suited to different applications depending on the specific material and cutting requirements.

1. Diamond Saw Blades

Diamond blades are the most common and preferred option for cutting artificial stone. These blades have diamond particles embedded in the cutting edge, which provide a superior cutting ability for hard materials.

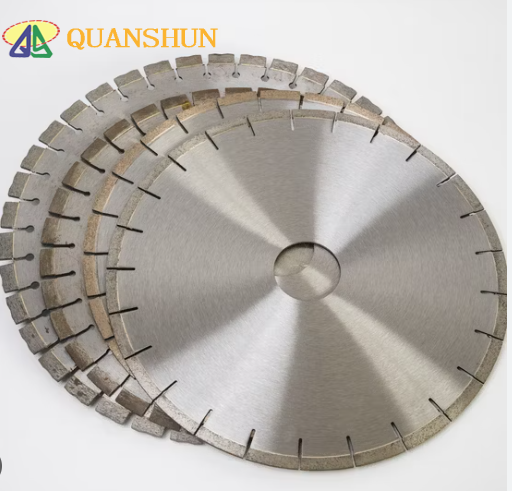

Continuous Rim Diamond Blades: These blades have a smooth cutting edge with no gaps or notches, making them ideal for precise, clean cuts. They are commonly used for cutting quartz countertops and other engineered stone surfaces.

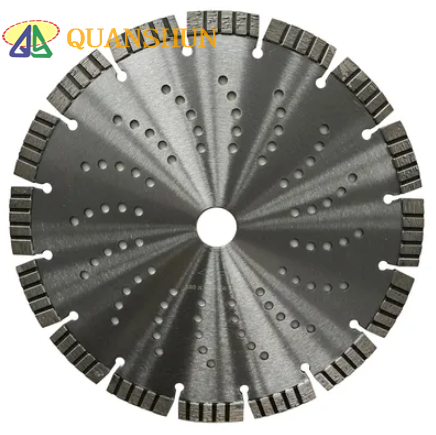

Segmented Diamond Blades: These blades feature a series of notched segments that provide a more aggressive cut. They are generally used for cutting thicker pieces of artificial stone or for rough cuts.

Turbo Diamond Blades: Turbo blades combine the advantages of continuous and segmented blades, offering faster cutting while maintaining smooth results. These are often used for cutting engineered stone quickly without sacrificing finish quality.

2. Resin-Bonded Saw Blades

Resin-bonded saw blades are often used for polishing or refining cuts made by diamond saw blades. These blades have a resin matrix that can hold abrasives, providing a smoother finish on the cut surface. They are particularly useful for achieving a high-gloss finish on artificial stone surfaces.

3. Vacuum Brazed Blades

These are specialized blades with diamond segments bonded using a vacuum brazing process. They are known for their precision and ability to cut through both natural and engineered stone materials, including granite, quartz, and artificial stone. Vacuum brazed blades are highly durable and produce minimal vibration during cutting.

Professional manufacturing:Geological drill bits, sandstone saw blades, wire saw blades, tower saw blades, mining saw blades, concrete saw blades, marble saw blades, ceramic saw blades, artificial stone saw blades, quartz stone saw blades

How to Choose the Right Saw Bl

How to Choose the Right Saw Bl

Why Special Saw Blades are Nee

Why Special Saw Blades are Nee

Artificial Stone Saw Blades: E

Artificial Stone Saw Blades: E

Quartz Stone Saw Blades: High-

Quartz Stone Saw Blades: High-