Quartz Stone Saw Blades: High-Performance Cutting Tools for Engineered Stone

Quartz stone saw blades are specially engineered cutting tools designed to process quartz stone and other high-hardness engineered stone materials. Due to the high quartz and silica content, quartz stone is extremely hard and abrasive, requiring saw blades with superior cutting strength, wear resistance, and heat control.

What Are Quartz Stone Saw Blades?

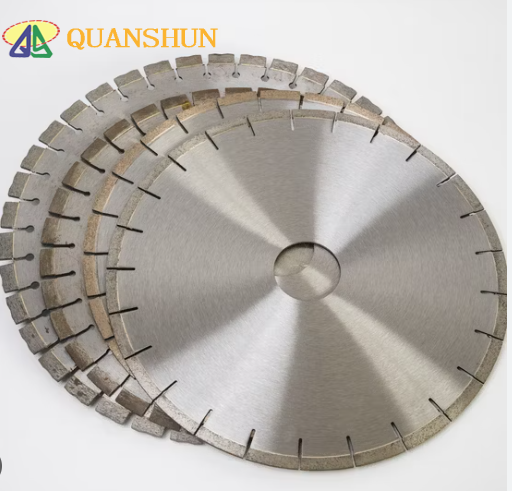

Quartz stone saw blades are circular diamond blades manufactured with premium synthetic diamonds and advanced metal bond technology. These blades are optimized to withstand the intense abrasion and heat generated when cutting quartz stone. They are commonly used with bridge saws, CNC machines, table saws, and stone processing equipment.

Challenges of Cutting Quartz Stone

Quartz stone presents several cutting challenges:

Very high hardness and density

High silica content causing rapid blade wear

Significant heat generation during cutting

Risk of edge chipping if improper blades are used

Specialized quartz stone saw blades are designed to overcome these challenges effectively.

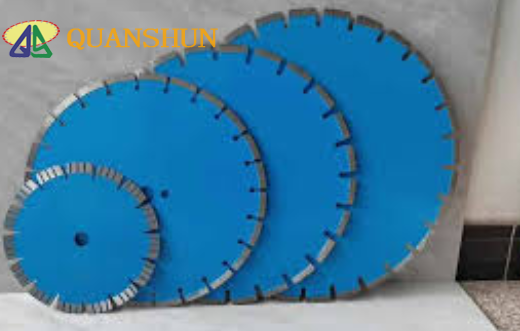

Types of Quartz Stone Saw Blades

Segmented Quartz Stone Blades

Provide fast cutting speed and excellent cooling. Ideal for thick slabs and heavy-duty industrial cutting.Turbo Quartz Stone Blades

Offer a balance between cutting efficiency and smooth cutting edges. Commonly used in countertop fabrication.Continuous Rim Quartz Stone Blades

Designed for precision cutting with minimal chipping. Suitable for finishing work and thin quartz slabs.

Wet Cutting Requirement

Quartz stone saw blades are strongly recommended for wet cutting:

Water reduces cutting temperature

Extends blade service life

Minimizes hazardous silica dust

Improves cutting accuracy and stability

Dry cutting quartz stone is not recommended due to excessive heat, blade wear, and health risks.

Applications

Quartz stone saw blades are widely used in:

Quartz countertop cutting and shaping

Engineered stone slab processing

Kitchen and bathroom surface fabrication

CNC stone cutting operations

Commercial and residential interior projects

Key Factors When Choosing a Quartz Stone Saw Blade

When selecting a quartz stone saw blade, consider:

Quartz content and slab thickness

Blade diameter and arbor size

Machine power and cutting speed

Bond hardness and segment design

Required edge quality and production efficiency

Choosing the correct blade significantly improves productivity and reduces cutting costs.

Maintenance and Safety Tips

Always use adequate water during cutting

Avoid excessive feeding pressure

Dress the blade regularly to maintain sharpness

Inspect the blade for cracks or uneven wear

Use proper dust control and personal protective equipment

Conclusion

Quartz stone saw blades are essential tools for efficient and precise cutting of quartz and engineered stone materials. With advanced diamond technology and specialized design, these blades deliver excellent cutting performance, long service life, and reliable results. Selecting the right quartz stone saw blade ensures high-quality finishes, safer operation, and lower overall production costs.

Artificial Stone Saw Blades: E

Artificial Stone Saw Blades: E

Quartz Stone Saw Blades: High-

Quartz Stone Saw Blades: High-

Artificial Stone Saw Blades: E

Artificial Stone Saw Blades: E

Ceramic Saw Blades: Precision

Ceramic Saw Blades: Precision