How to Choose the Right Saw Blade for Artificial Stone

For cutting artificial stone, you need a diamond saw blade, as the material is very hard. The specific type of diamond blade will depend on whether you need a smooth, chip-free finish or a faster, more aggressive cut.

Selecting the right saw blade for artificial stone depends on several factors, including the material you are working with, the thickness of the stone, and the desired cutting finish. Here’s a guide to help you choose:

1. Material of the Artificial Stone

Quartz-based Stone: Due to its hardness, you’ll need a blade with a high diamond concentration and a continuous rim to avoid chipping.

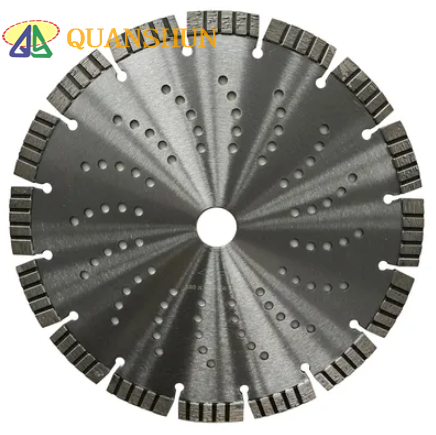

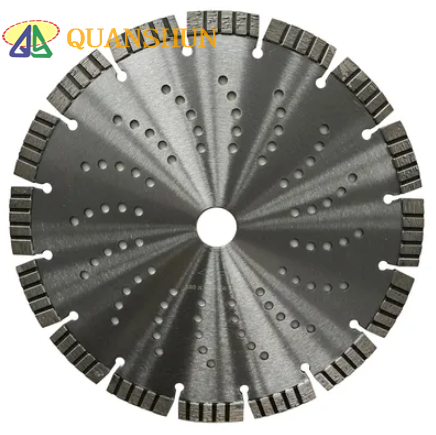

Marble and Granite Composites: These materials are a bit softer than pure quartz, so a segmented or turbo diamond blade could be effective for quicker cuts.

2. Type of Cut

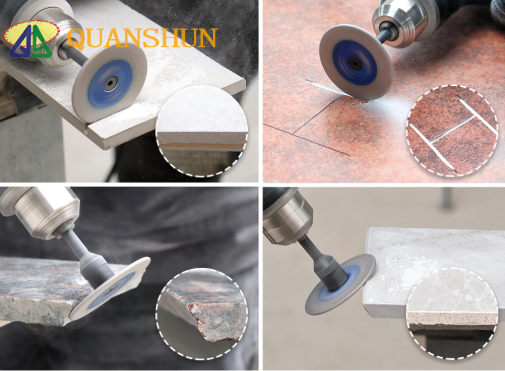

Straight Cuts: For clean, straight cuts on artificial stone, opt for continuous rim diamond blades or resin-bonded blades for a polished finish.

Rough Cuts: For cutting thick slabs or rough edges, segmented or turbo diamond blades are ideal, as they are designed for faster cutting and removing material quickly.

Polishing: If your goal is to achieve a smooth, polished finish after the cut, use resin-bonded or polishing diamond blades.

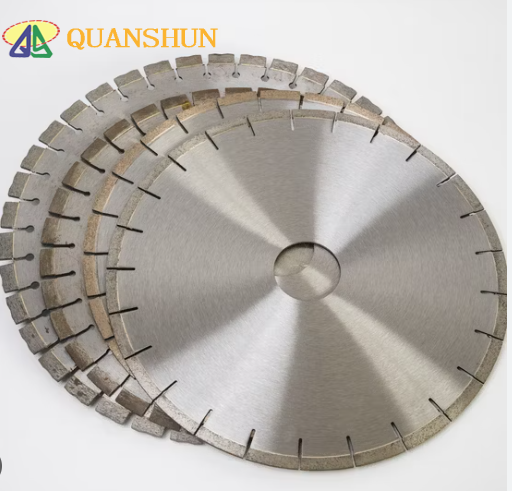

3. Blade Diameter and Thickness

For small, detailed cuts, choose a thinner, smaller diameter blade.

For larger slabs, you’ll need a thicker, larger blade for stability and to cut through the material without risk of warping or damage.

4. Blade Quality and Durability

Choose a high-quality diamond blade with a longer lifespan to minimize frequent replacements. High-quality blades often feature a higher concentration of diamonds, which translates to better cutting performance and longevity.

5. Cooling and Dust Control

Water-Cooled Blades: Many artificial stone saw blades are designed to be used with water cooling systems to reduce dust generation and prolong the life of the blade. Water also helps prevent overheating, which can cause the blade to wear out prematurely.

Dust Collection Systems: Consider blades designed with a dust control system or use a separate dust collection unit to protect both the operator and the work environment.

Tips for Cutting Artificial Stone

Always Use Proper Safety Gear: Artificial stone cutting produces fine dust and sharp debris. Wear safety glasses, a dust mask, ear protection, and gloves when operating saws.

Use Water or Lubrication: When using diamond blades, consider using water to reduce heat and dust while increasing the life of the blade.

Avoid Overheating: Cutting artificial stone generates a lot of heat. Make sure to let the blade cool down if it starts overheating, or use water-cooling methods if applicable.

Slow, Steady Cuts: Avoid pushing the blade too fast; let the saw do the work. Fast cuts may cause chipping or unnecessary wear on the blade.

Conclusion

Artificial stone saw blades are specialized tools that allow professionals to cut and shape engineered stone materials with precision and efficiency. By choosing the right type of blade for your specific material and cutting needs, you can ensure clean cuts, reduce blade wear, and achieve the desired finish. Whether you’re working with quartz, marble composites, or granite, using the proper blade is critical to getting the best results.

With the increasing popularity of artificial stone in residential and commercial projects, understanding the importance of the right saw blade is key for professionals looking to maintain quality and productivity in their work.

Marble Saw Blades: A Complete

Marble Saw Blades: A Complete

How to Choose the Right Saw Bl

How to Choose the Right Saw Bl

Why Special Saw Blades are Nee

Why Special Saw Blades are Nee

Artificial Stone Saw Blades: E

Artificial Stone Saw Blades: E