Diamond Wire & Band Saw Blades Archives

Wire saw blades are widely used across various industries due to their high precision, cutting efficiency, and adaptability to complex cutting conditions. Compared with traditional cutting tools, wire saw blades offer superior performance in cutting hard, brittle, and high-value materials, making them an essential solution in modern industrial processing.

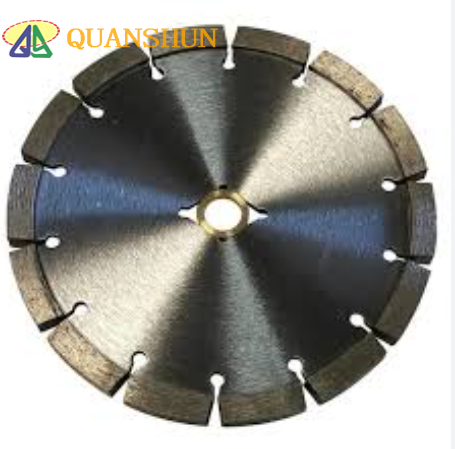

1. Stone Quarrying and Processing

Wire saw blades are extensively applied in the stone industry for quarrying and processing natural stones such as marble, granite, limestone, and sandstone.

Typical applications include:

Block extraction in quarries

Primary cutting of large stone blocks

Profiling and shaping of stone products

Advantages:

Narrow cutting kerf and low material loss

Smooth cutting surface with minimal damage

Reduced noise and vibration

Improved safety and environmental protection

Wire saw technology has gradually replaced traditional blasting and disc cutting methods in modern stone quarry operations.

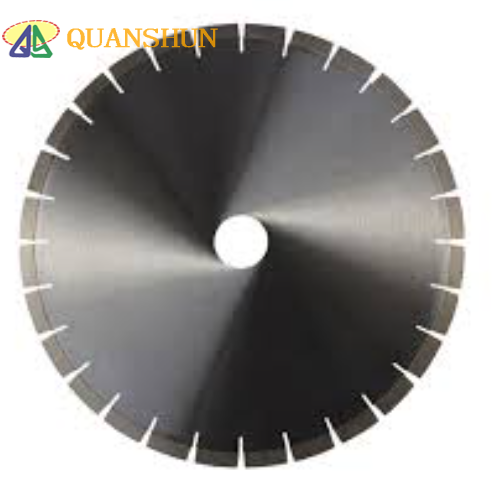

2. Construction and Concrete Cutting

In the construction and demolition industry, wire saw blades are commonly used for cutting reinforced concrete structures.

Typical applications include:

Bridge and tunnel modification

Building renovation and partial demolition

Cutting of thick concrete walls and foundations

Underwater concrete cutting

Advantages:

Capable of cutting large and thick structures

Flexible cutting direction without depth limitation

Low vibration, preventing secondary structural damage

Suitable for confined or sensitive working environments

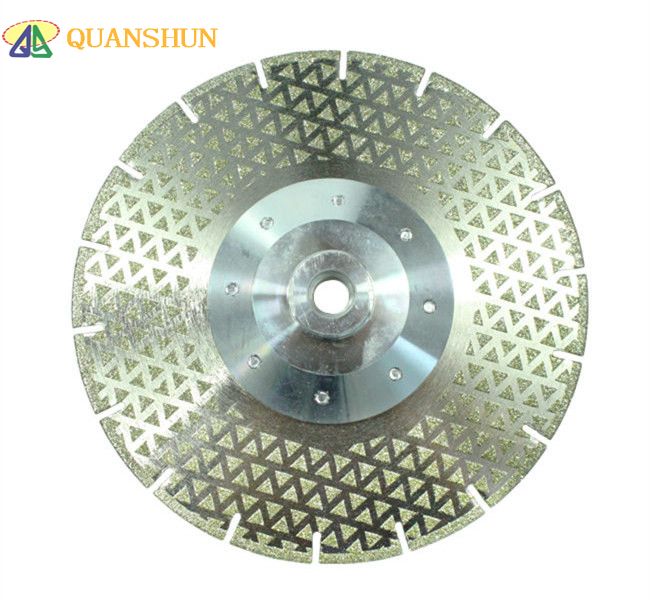

3. Semiconductor and Photovoltaic Industry

Wire saw blades play a critical role in high-precision cutting applications such as:

Silicon ingot slicing

Sapphire and silicon carbide (SiC) cutting

Photovoltaic wafer production

Advantages:

High cutting accuracy and consistency

Ultra-thin slicing to minimize material waste

Low cutting stress, reducing micro-cracks

Suitable for high-speed, continuous production

These characteristics make wire saw blades indispensable in semiconductor and solar energy manufacturing.

4. Metal and Special Material Cutting

Wire saw blades can also be used for cutting difficult-to-machine materials, including:

Stainless steel

Titanium alloys

High-strength alloy steels

Composite materials

Advantages:

Stable cutting performance on hard materials

Minimal deformation during cutting

Suitable for precision and customized cutting tasks

They are widely used in aerospace, defense, and high-end manufacturing industries.

5. Precision and Customized Applications

Wire saw blades are ideal for precision and customized cutting requirements in:

Laboratories and research institutions

Prototype manufacturing

Irregular and complex-shaped workpieces

Their flexibility and controllability make them an excellent choice for R&D and specialized processing applications.

Conclusion

Thanks to their precision, efficiency, and versatility, wire saw blades have become an important cutting solution across industries such as stone processing, construction engineering, semiconductor manufacturing, and advanced material processing. As industrial demands continue to evolve, wire saw blades will play an increasingly important role in future cutting technologies.

Golden 5-150mm Porcelain Tile

Golden 5-150mm Porcelain Tile

1.6mm 1.8mm Electroplated Diam

1.6mm 1.8mm Electroplated Diam

Diamond Wire & Band Saw Bl

Diamond Wire & Band Saw Bl

Marble Saw Blades: A Complete

Marble Saw Blades: A Complete