Key Features & Engineered Benefits

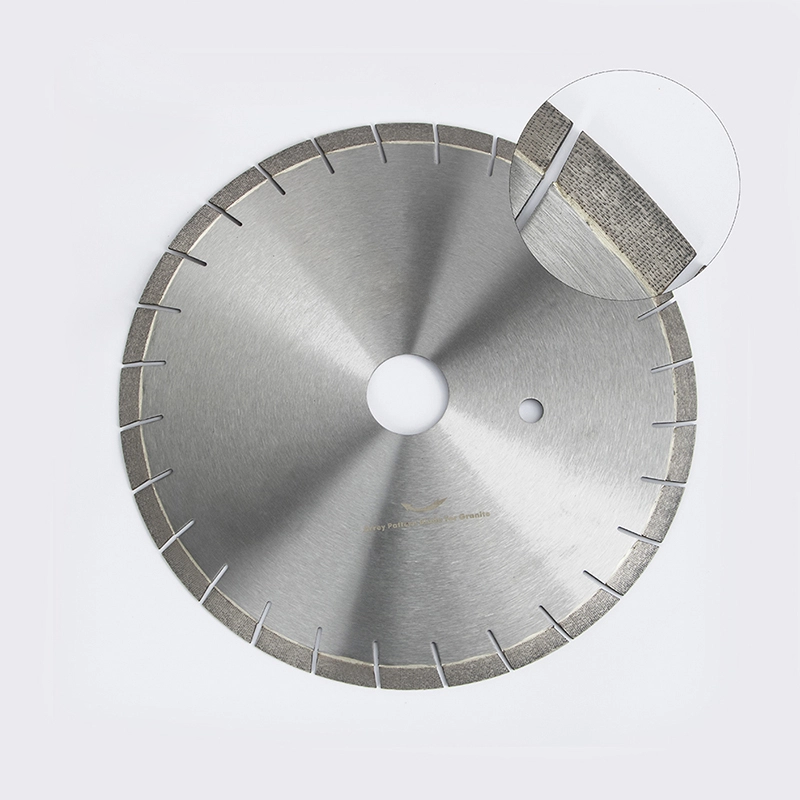

1. Unmatched Cutting Precision & Surface Finish

Crafted with a specialized bond matrix and premium synthetic diamonds, this blade is optimized for marble's specific hardness. It delivers impeccably smooth, chip-free cuts with a polished edge quality straight from the saw, drastically reducing the need for secondary edge finishing. This is critical for seamless joins in countertops and the pristine edges required for luxury installations.

2. High-Efficiency Design for Faster Production

The blade’s formula features a bond that allows the diamond grit to wear at a controlled, optimal rate. This self-sharpening action maintains a consistently sharp cutting edge, enabling faster feed rates with less operator pressure. The result is significantly reduced cutting time, lower machine wear, and increased job-site productivity.

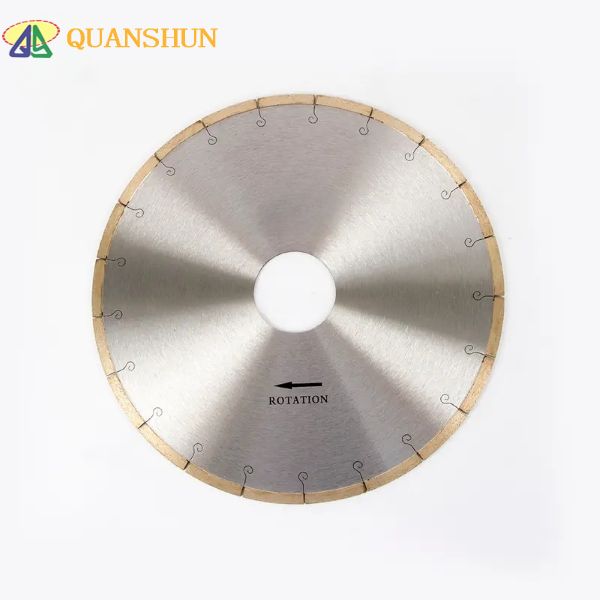

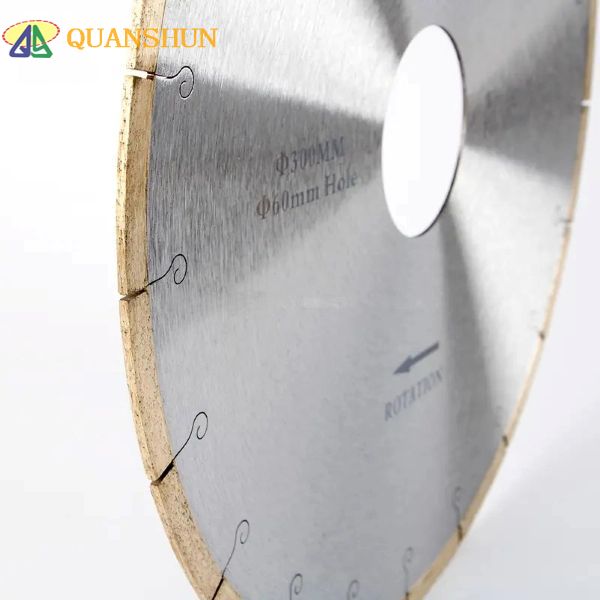

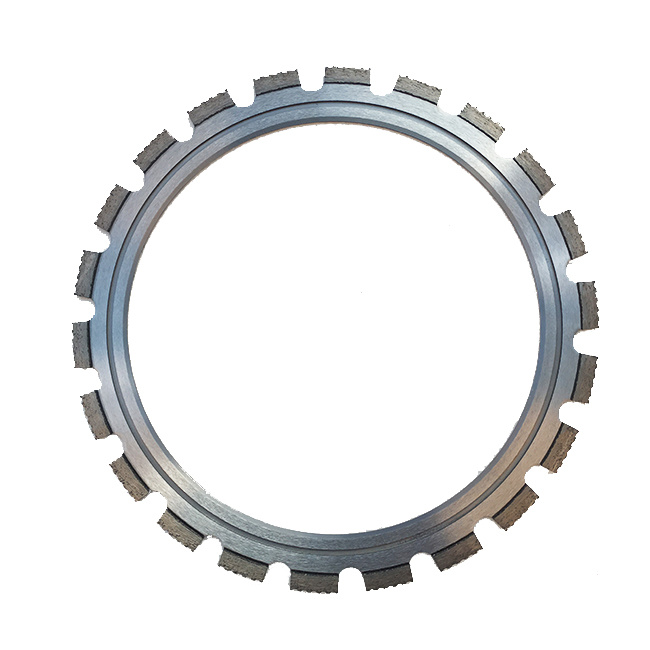

3. Vibration-Reduced, Quiet Operation for Enhanced Control

Precision-laser-cut expansion slots (gullets) are strategically placed around the 300mm steel core. These slots effectively dampen harmonic vibration and reduce operational noise, promoting a smoother, more stable cut. This stability minimizes blade wander, increases cutting accuracy, and reduces user fatigue during extended operation.

4. Extended Service Life for Maximum ROI

By pairing a marble-specific bond with high-concentration, industrial-grade diamonds, this blade achieves an ideal balance between aggressive cutting and remarkable longevity. It is built to withstand the demands of professional shop use, ensuring consistent performance and outstanding cost-per-cut value over its extended service life.

5. Optimized for Wet Cutting Performance

Designed as a wet-cut blade, it performs best with water cooling. Water is essential for suppressing hazardous silica dust, dissipating heat to prevent thermal damage to both the marble and the blade's segments, and flushing away cutting slurry for a clear view of the guide line. Always follow the marked "ROTATION" direction for safe and effective operation.