Product Overview

Our Professional Diamond Saw Blade is engineered specifically for high-performance dry or wet cutting of granite, engineered quartz, and other hard, abrasive natural and artificial stone. Available in diameters from 300mm to 500mm, this blade features a precision-engineered array pattern of diamond-impregnated segments designed to deliver a superior balance of aggressive cutting speed, exceptional blade life, and a smooth, chip-free finish. Ideal for slab fabrication, countertop installation, and monument work, it is the reliable choice for professionals who demand efficiency and quality in every cut.

Key Features & Benefits

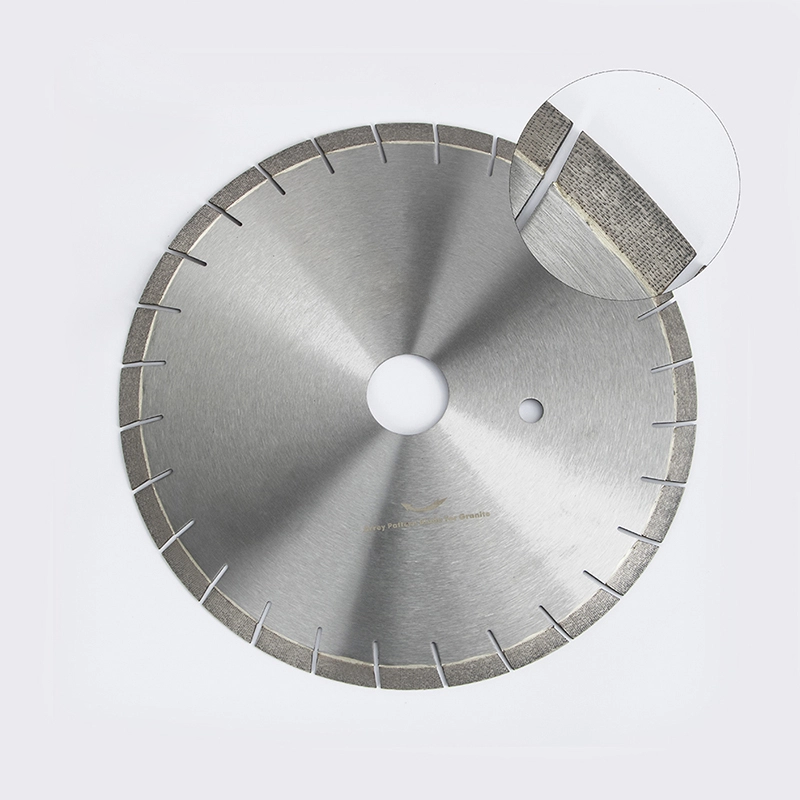

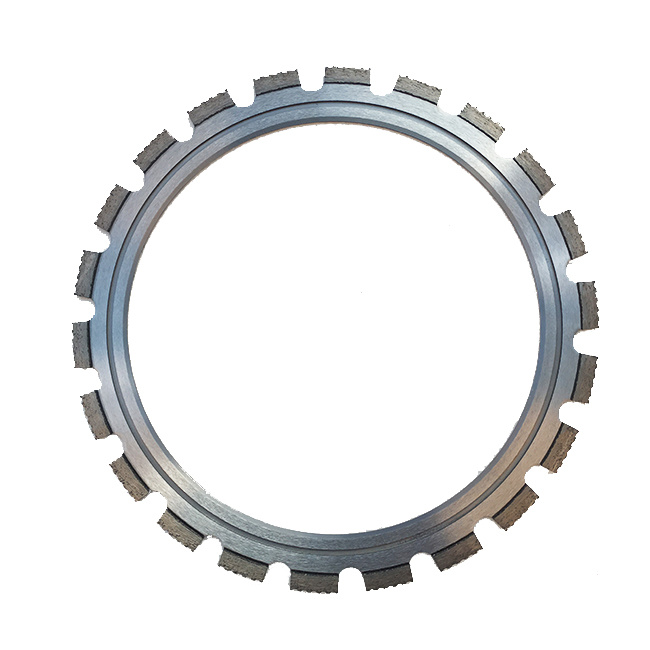

Advanced Array Segment Pattern: The blade utilizes a specialized segment arrangement. The closely spaced, high-concentration diamond segments combined with strategically placed laser-cut expansion slots (visible in images) facilitate efficient heat dissipation and rapid debris removal. This design minimizes blade warp, reduces friction, and enables faster, cooler, and smoother cutting action through dense materials.

Premium Diamond Grit & Bond Matrix: Each segment is formulated with a high density of premium synthetic diamond crystals within a specially engineered metal bond. This proprietary formula is optimized for the hardness and abrasiveness of granite and quartz, ensuring the diamonds are continuously exposed for sharp, fast cutting while the bond wears at a controlled rate to maximize the total usable life of the blade.

Precision-Engineered Steel Core: The blade core is manufactured from high-tensile, laser-cut steel to exacting tolerances. The core thickness is meticulously calibrated for each diameter (from 2.2mm to 3.2mm) to provide optimal rigidity and vibration dampening. This ensures straight, accurate cuts with minimal blade deviation and reduced noise during operation.

Optimized Segment Geometry & Cooling: The segment dimensions (Height, Width, Length) are scientifically calculated for each blade size. The segments feature a chamfered or turbo-style edge (as seen in close-up images) that bites aggressively into the material. The slots between segments act as effective coolant channels, further enhancing cutting performance and blade longevity, whether used wet or dry.

Professional-Grade Application: Designed explicitly for the rigors of stone fabrication shops and installation sites. It delivers clean, precise cuts in granite slabs, quartz countertops, and other hard stone, minimizing edge chipping and reducing the need for secondary finishing work, thereby increasing on-site productivity.

Technical Specifications

The following table details the standard specifications for our Diamond Blade in the Array Pattern for granite and quartz.

Diameter (mm) | Core Thickness (mm) | Segment Dimension (mm) | Segment Number | |

|---|---|---|---|---|

300 | 2.2 | 44/40 * 3 * 15(20) | 21 | |

350 | 2.4 | 44/40 * 3.2 * 15(20) | 24 | |

400 | 2.8 | 44/40 * 3.6 * 15(20) | 28 | |

450 | 3.0 | 44/40 * 4.0 * 15(20) | 32 | |

500 | 3.2 | 44/40 * 4.2 * 15(20) | 36 |