What is a diamond grinding wheel for a grinding machine?

Views :

Update time : 2026-01-08

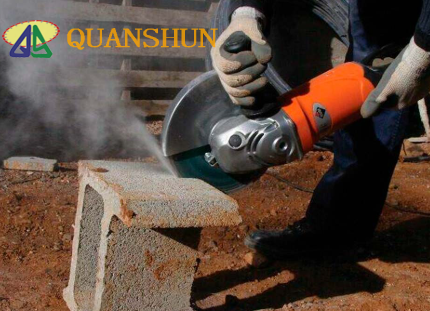

A grinder diamond disc is a durable cutting/grinding wheel with industrial diamonds embedded in its edge, used with angle grinders to cut hard materials like concrete, tile, stone, metal, and rebar, offering faster, cleaner cuts than traditional abrasive wheels, though at a higher initial cost. Key features include material-specific designs (turbo, segmented, continuous rim) for different applications, self-sharpening grit, and directional arrows for proper mounting, ensuring efficient, long-lasting performance.

Diamond discs are versatile accessories for construction and DIY projects, prized for their efficiency and durability. The specific type you need depends on the material you're working with and the required finish.

Types & Uses:

- Universal: For general construction materials like concrete, brick, and stone.

- Turbo/Segmented: Aggressive cuts for concrete, pavers, and masonry, with slots for cooling and debris removal.

- Metal Cutting: Vacuum-brazed for cutting steel, rebar, and heavy metal.

- Tile/Porcelain: Precision-designed for smooth, chip-free cuts on ceramics.

Key Features:

- Diamond Grit: Provides the cutting edge, often mixed for optimal performance in specific materials.

- Steel Core: Strong base for impact and temperature resistance.

- Arbor Hole: Standard sizes (e.g., 22.23mm or 7/8") fit most angle grinders.

- Self-Sharpening: Grits expose new diamond as they wear, extending life.

How to Use:

- Check Direction: Ensure the rotational arrow on the disc points in the direction the grinder spins.

- Mount Securely: Attach the raised hub side towards the machine.

- Use Water (Optional): Can help cool rougher, dry-cut discs, but many modern discs are designed for dry use, with slots aiding cooling.

Benefits:

- Longer Life: Lasts significantly longer than abrasive wheels.

- Faster & Cleaner Cuts: More efficient, with less chipping.

- Versatile: One disc can often handle many materials.

Related News

Read More >>

Quartz Stone Saw Blades: High-

Quartz Stone Saw Blades: High-

01 .12.2026

Quartz stone saw blades are specially engineered cutting tools designed to proce

Artificial Stone Saw Blades: E

Artificial Stone Saw Blades: E

01 .12.2026

Artificial stone saw blades are specially designed cutting tools used for proces

Ceramic Saw Blades: Precision

Ceramic Saw Blades: Precision

01 .12.2026

Ceramic saw blades are specialized cutting tools designed for clean, accurate, a

Marble Saw Blades: Precision C

Marble Saw Blades: Precision C

01 .12.2026

Marble saw blades are specialized cutting tools designed for accurate and effici