Concrete Saw Blades: Types, Applications, and Performance

Concrete saw blades are specialized cutting tools designed to cut through hard construction materials such as concrete, reinforced concrete, asphalt, brick, and stone. They are widely used in construction, roadwork, demolition, and renovation projects. Choosing the right concrete saw blade is essential for achieving clean cuts, high efficiency, and long service life.

What Are Concrete Saw Blades?

Concrete saw blades are circular blades typically embedded with industrial-grade diamond segments along the cutting edge. Diamonds are used because they are extremely hard and resistant to wear, making them ideal for cutting abrasive materials like concrete. These blades are mounted on machines such as handheld saws, floor saws, wall saws, or table saws.

Types of Concrete Saw Blades

Concrete saw blades can be classified based on several factors:

By Cutting Method

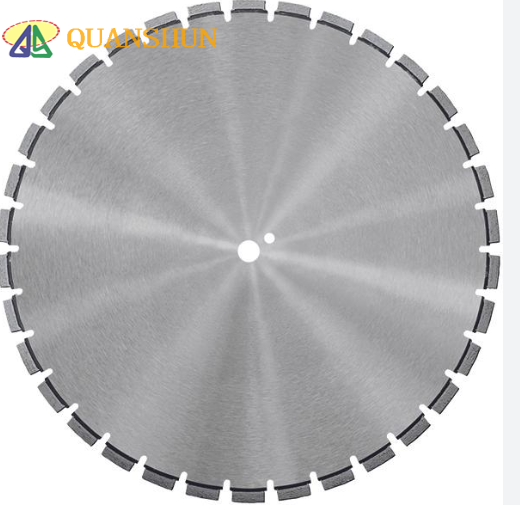

Wet Cutting Blades: Require water during cutting to reduce dust, cool the blade, and extend blade life. Commonly used for heavy-duty and continuous cutting.

Dry Cutting Blades: Designed to cut without water, usually in short intervals to prevent overheating. Suitable for small jobs or locations without water supply.

By Bond Hardness

Soft Bond Blades: Used for cutting hard concrete. The softer bond wears faster, exposing new diamonds.

Hard Bond Blades: Used for cutting soft or abrasive materials like green concrete or asphalt.

By Segment Design

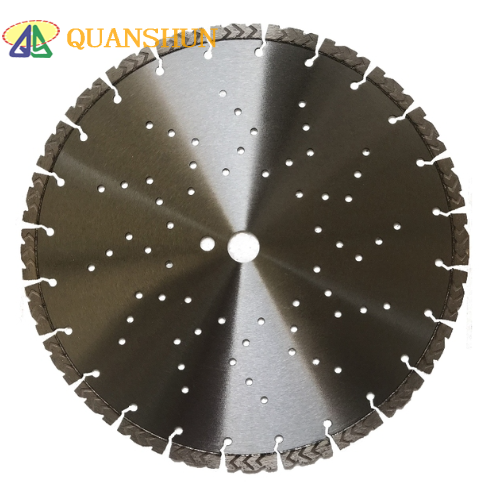

Segmented Blades: Fast cutting and good cooling, ideal for general construction.

Turbo Blades: Offer a balance between speed and smoothness.

Continuous Rim Blades: Provide smooth cuts, often used for decorative or precision work.

Applications

Concrete saw blades are widely used in:

Cutting concrete slabs, walls, and floors

Road and bridge construction

Expansion joint cutting

Removal of damaged concrete

Cutting reinforced concrete with steel rebar

Key Factors When Choosing a Concrete Saw Blade

When selecting a concrete saw blade, consider the following:

Type and hardness of the material

Blade diameter and arbor size

Cutting method (wet or dry)

Machine power and speed

Required cutting speed and finish quality

Using the correct blade not only improves cutting efficiency but also reduces machine wear and increases operator safety.

Maintenance and Safety

To maximize blade life and ensure safe operation:

Use the blade for its intended material

Avoid excessive pressure during cutting

Ensure proper cooling, especially for wet blades

Inspect blades regularly for damage

Always follow safety guidelines and wear protective equipment

Conclusion

Concrete saw blades are essential tools in modern construction and infrastructure projects. With various designs and specifications available, selecting the right blade for the job can significantly improve performance, reduce costs, and enhance safety. Understanding blade types, applications, and proper usage helps professionals achieve optimal cutting results.

Quartz Stone Saw Blades: High-

Quartz Stone Saw Blades: High-

Artificial Stone Saw Blades: E

Artificial Stone Saw Blades: E

Ceramic Saw Blades: Precision

Ceramic Saw Blades: Precision

Marble Saw Blades: Precision C

Marble Saw Blades: Precision C