Laser Welded Diamond Saw Blades for Stone and Concrete: High-Performance Diamond Tools for Professional Cutting

In the modern construction and stone-processing industry, cutting efficiency, precision, and stability are critical to achieving high-quality results. Laser welded diamond saw blades have become the preferred choice for professionals working with stone, granite, marble, reinforced concrete, asphalt, and other hard materials. Their outstanding durability, strong welding strength, and exceptional cutting performance make them essential tools in demanding job sites.

1. What Are Laser Welded Diamond Saw Blades?

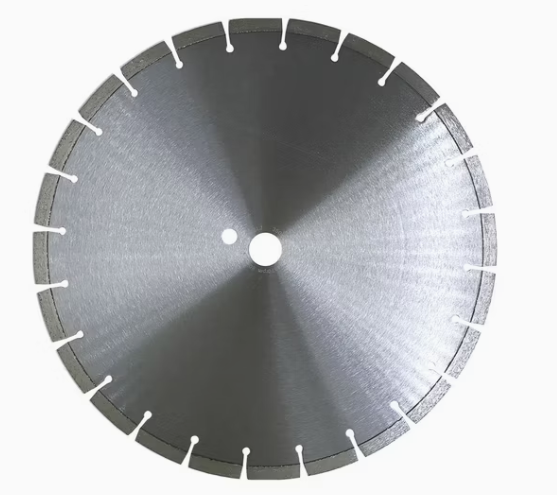

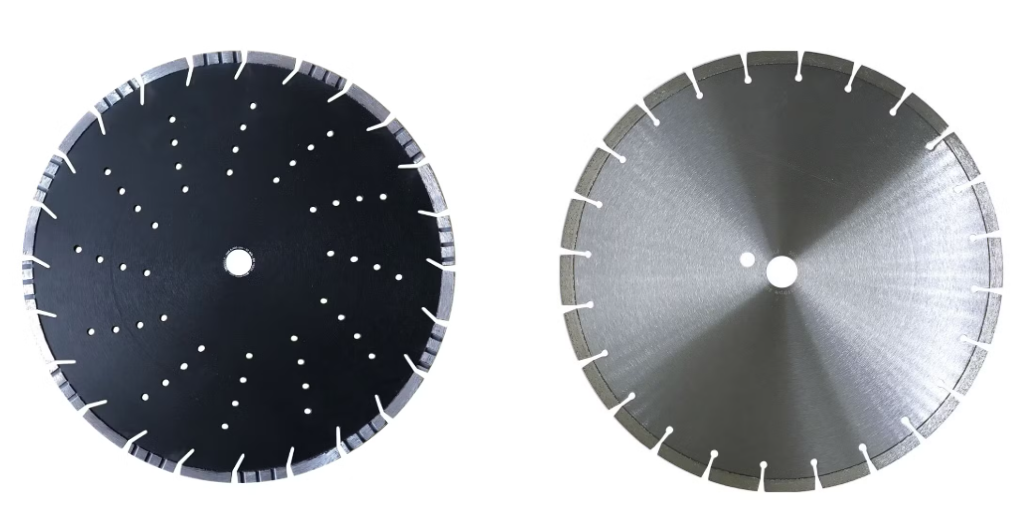

Laser welded diamond blades are produced using high-energy laser technology to firmly bond the diamond segments to the steel core. Unlike traditional silver brazed blades, laser welding creates a deep-penetrating, metallurgical bond that can withstand extremely high temperatures and heavy-duty applications.

Key Structural Components:

Steel Core: High-strength alloy steel ensures blade stability at high RPM.

Diamond Segments: Made from premium synthetic diamonds and metal powders, providing sharpness and long service life.

Laser Welding: High-temperature fusion ensures the segments are securely attached, making the blade suitable for both wet and dry cutting.

2. Advantages of Laser Welded Diamond Saw Blades

✓ Superior Welding Strength

Laser welding creates a solid, permanent joint between the segment and steel body, preventing segment loss even under extreme cutting conditions.

✓ Excellent Cutting Performance

The diamond segments deliver fast cutting speed while maintaining smooth and accurate edges on stone and concrete.

✓ High Temperature Resistance

Laser welded blades tolerate high heat levels generated during dry cutting, making them ideal for heavy-duty tasks.

✓ Long Service Life

Optimized diamond concentration and segment design provide extended usage compared to ordinary blades.

✓ Versatile Cutting Ability

Suitable for both wet and dry applications, meeting various job site requirements.

3. Application Fields

Laser welded diamond saw blades are widely used in:

● Stone Industry

Granite slabs & blocks

Marble tiles & countertops

Quartz stone & engineered stone

Basalt, sandstone, limestone

● Construction & Concrete Work

Reinforced concrete cutting

Masonry bricks and blocks

Cement products

Concrete pipes

Wall chasers and floor saws

● Road & Civil Engineering

Asphalt cutting

Highway and pavement repair

Expansion joint cutting

● Industrial & Professional Use

Bridge construction

Building demolition

Hard material processing

4. Segment Designs for Different Materials

1)Segmented Type

Best for concrete, reinforced concrete, and granite

Excellent heat dissipation

Fast cutting speed

2)Turbo Type

Ideal for marble, sandstone, and medium-hard stone

Provides smoother cutting and reduced chipping

3)Continuous Rim

Suited for delicate materials and fine cutting

Minimal edge chipping on marble and ceramics

5. Why Choose Laser Welded Diamond Tools?

Maximum safety – strong segments that won’t detach

Higher cutting efficiency – saves labor and time

Better cost performance – long lifespan reduces tool replacement cost

Professional results – cleaner cuts and improved finish quality

Whether used with handheld saws, bridge saws, floor saws, or angle grinders, laser welded blades consistently deliver reliable cutting performance in harsh working conditions.

Laser welded diamond saw blades represent the highest standard in modern cutting technology. With strong welding strength, excellent durability, and precision cutting ability, they are the ideal choice for professionals in stone fabrication, construction, and civil engineering. Whether you are working with granite, marble, concrete, or asphalt, these blades offer superior performance you can trust.

Quartz Stone Saw Blades: High-

Quartz Stone Saw Blades: High-

Artificial Stone Saw Blades: E

Artificial Stone Saw Blades: E

Ceramic Saw Blades: Precision

Ceramic Saw Blades: Precision

Marble Saw Blades: Precision C

Marble Saw Blades: Precision C